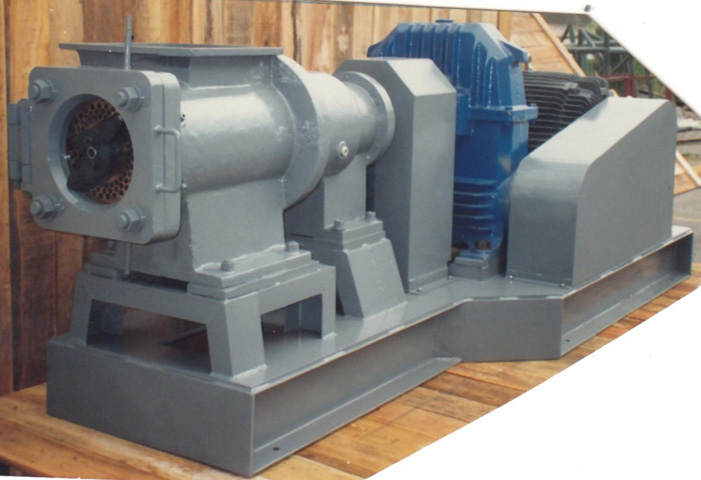

The Hammermill is designed for both pre-cleaning and size reduction of rubber in the form of lumps or crepes. It basically comprises a rigid steel casing enclosing a high-speed rotor carrying multiple free swinging or fixed crushing hammers.

For the processing of rubber crepes, a pair of top-mounted cast ferro-chrome Creper rolls serves to impart more shearing on the rubber as well as to control the feeding rate. Machine throughput varies from 1 to 2 Ton drc / hr depending on the selection of discharge screen apertures.

This is a wet processing machine designed to shear rubber to a form that dries easily, quickly, and economically and free of "knuckles". An outer cutter is incorporated to pelletize the rubber for easy transfer by a vortex pump or other pneumatic devices. The final product is generally homogeneous and consistent in quality.

The Extruder can be used as an intermediate or final machine. It can also be used in tandem through a two-stage "course" and "fine" processing as desired. A selection of models are available with machine throughputs ranging from 500 to 1500 kg drc / hr.

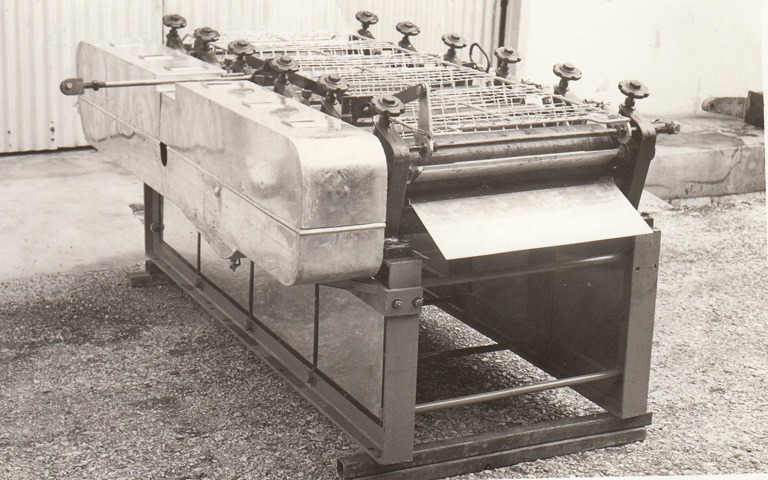

A well-established machine that is used all over the world since it's first introduction in the 1930's. It is designed exclusively for the sheeting and final ribbing of latex coagula prior to smoking in the processing of RSS or "ribbed, smoked sheet" rubber.

The use of a proprietary device with multi-disc Aluminium trays prevents jamming and ensures optimum tension thus enabling the transfer of rubber sheets between any pairs of rollers to be smooth, efficient and fully automatic. Models with either 5 or 6 pairs of rollers are available. Machine throughput is up to 1000 kg drc / hr.